Vacuum mixer

1、Vacuum mixer adopts the principle of 45 degrees centrifugation, through revolution and the assistance of vacuum pump, the micron bubbles can be quickly eliminated, and the rotation makes the different components of the material fully mixed evenly, no stratification, no bubbles. The stirring defoaming effect is extremely ideal. 2、Vacuum mixer No stirring appliance extends into the material, no need to clean, will not pollute the raw materials, and will not cause the loss of materials because the mixer takes away the material; A total of 10 groups of data can be stored, each group can be divided into 5 sections to adjust the speed and time, vacuum state can be freely selected to open or close;Vacuum mixer

Vacuum Mixer Technical Parameters:

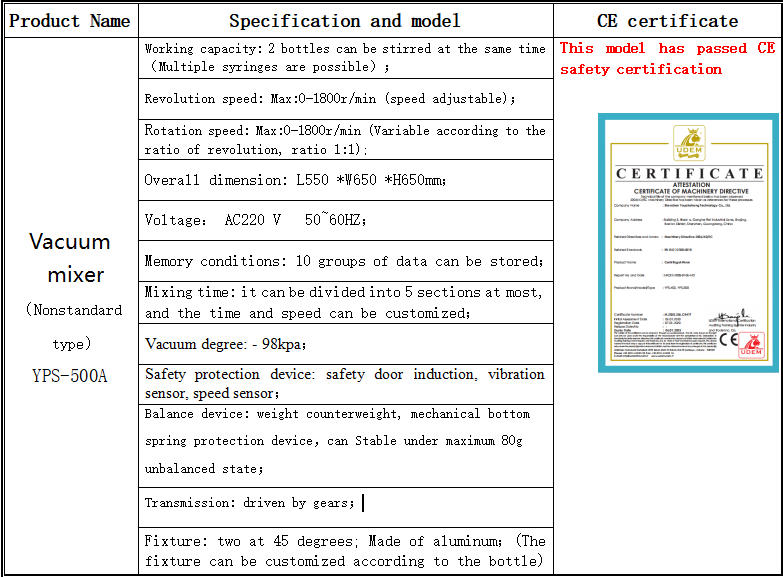

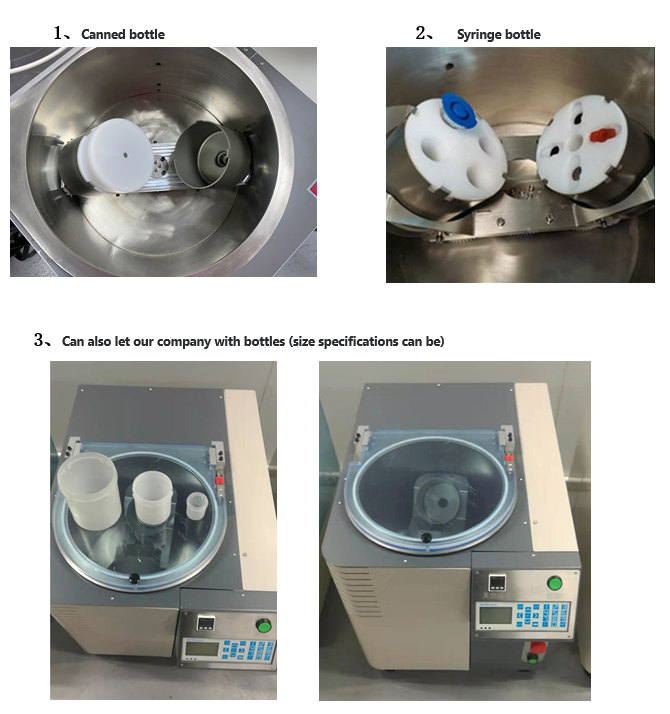

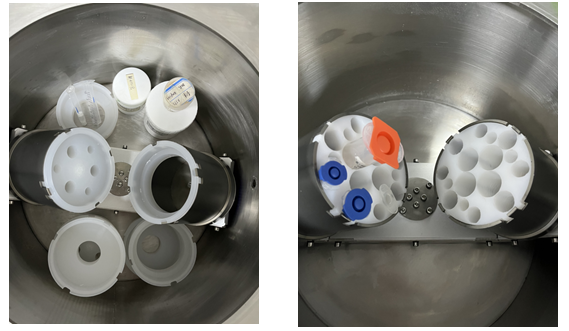

The fixture can be customized to different specifications according to customer bottles:

4、A single machine can be used for a variety of bottles (you can also mix a single bottle and use a counterweight on the other side)

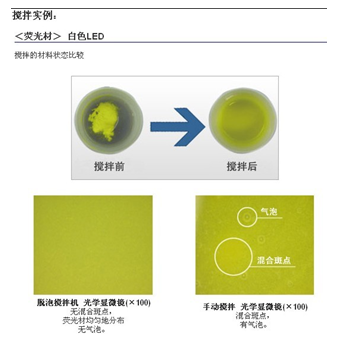

Material mixing comparison

Comparison of phosphor before and after defoaming and stirring

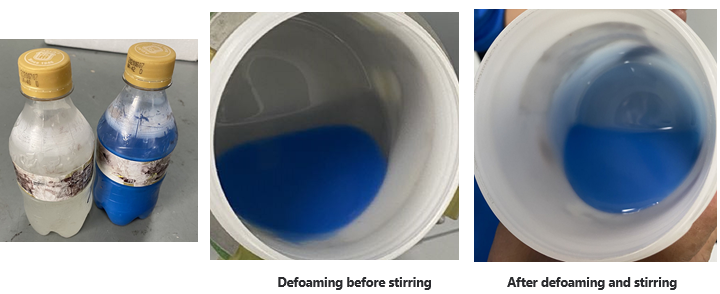

Comparison of epoxy glue before and after mixing (two kinds of glue mixed and defoaming)

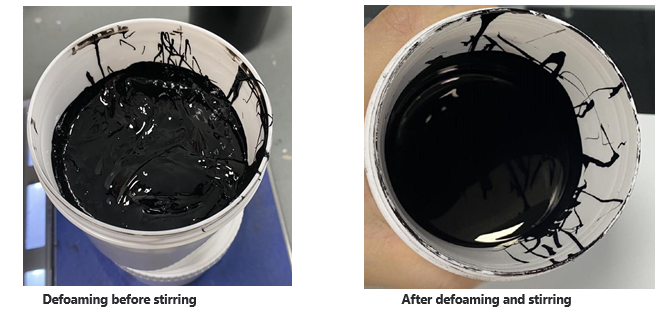

Ink before and after mixing:

Simple operation: