Function: solder paste timing temperature return machine, a machine with multiple slots, can be used for multiple bottles of solder paste temperature return, intelligent temperature return, effective control of solder paste temperature return time, ensure solder paste activity, paint appearance, smooth surface, neat and beautiful 2.1 Assembly and production of imported electrical parts; 2.2 Each tin paste placement tank has an independent time control. When the time is set, the tin paste can will automatically sink, and the tin paste will automatically pop out after the return temperature is completed. 2.3 Multiple cans of 500G solder paste can be warmed at the same time; Note: In the case of sudden power failure, if the set time is not reached, the solder paste bottle will automatically pop out; 3.1 Installation 3.1.1 Please place the machine on a horizontal and stable table or ground to avoid shaking; 3.1.2 Please check that the operating voltage specification of the machine (AC220v/60Hz) should be consistent with the voltage specification of the mains, and switch on the 220v power supply; 3.1.3 Please confirm whether there are foreign objects in the groove of the machine to avoid unnecessary trouble. 3.2 Debugging 3.2.1 Ensure that the machine is placed smoothly. 3.2.2 Turn on the power switch, manually put the solder paste or red glue to be returned to the temperature return machine slot, the indicator light is green, the solder paste can or red glue bottle will automatically sink after setting the time, and after reaching the set return temperature time, the return temperature will automatically pop out, the red alarm will flash and sound alarm will be raised. 3.2.3 Depending on solder paste quality and refrigeration conditions, adjust the panel time setting to the best return temperature time 3.2.4 After pressing the start switch, the optimal air pressure is 5 kg, and each can of solder paste can be operated independently. 4.1.0 After debugging, start the power supply. 4.1.1 Place the tin paste pot to be warmed into the fluted fixture. 4.1.2 Please start the corresponding power supply of the returned solder paste and wait for the return temperature. 4.1.3 Adjust the time setting on the panel to the better return temperature time; 4.1.4 After pressing the power switch, the solder paste can will automatically sink. The machine starts to warm up until it is finished and the tin paste can is free. 4.1.5 After use, turn off the power switch; 4.2 announcements 4.2.1 Please keep the machine clean; 4.2.2. Check that the screws are not loose; 4.2.3 Check the main power switch of the machine before temperature return; Four-slot machine size: L500*W300*H230(mm) Eight slot machine size: L500*W520*H320(mm) 12-slot machine size: L710*W530*H380(mm) 15 slot machine size: L600*W708*H450(mm) All products can be customized according to customer bottles and requirements Machine weight: Net weight 4 slots /15KG, 8 slots /35KG, 10 slots /45KG, 12 slots /68KG Working capacity: 4 cans, 8 cans, 10 cans, 12 cans; Each can is 500g Working voltage: 220V 60Hz Optimum air pressure: 5KG

1. Using PLC control, imported electrical parts assembly production 2. Each tin paste placement tank has an independent time control. The tin paste can will automatically sink when the time is set, and the tin paste will automatically pop out after the return temperature is completed. 3. In the case of power failure, if the set time is not reached, the solder paste bottle will automatically pop out. 4. Solder paste cans of different specifications and models can be used on the same equipment. 5. Can customize 4 stations, 8 stations, 12 stations and other multi-station. 1. Please place the machine on a horizontal and stable table or ground to avoid shaking. 2. Please check that the operating voltage specification (AC220V) of the machine should be consistent with the voltage specification of the mains, and switch on the 220V power supply. 3. Please confirm whether there are foreign bodies in the groove of the machine to avoid unnecessary trouble. 1. Make sure the machine is placed smoothly. 2. Place the solder paste can to be warmed completely in the groove fixture of the machine, and then start the corresponding power supply solder paste to automatically sink and start the heating. After the heating of the solder paste is completed, it will automatically pop out. 3. Depending on the solder paste quality and refrigeration conditions, adjust the panel time setting to the best return temperature time. 4. After pressing the start switch, the air pressure is 5 kg, and each tin paste can be operated independently. 1. After commissioning, power on. 2. Place the tin paste can to be warmed into the fixture in the groove. 3. Start the corresponding power supply for the tin paste to be warmed 4. Adjust the time setting on the panel to the best return time. 5. After pressing the power switch, the solder paste can will automatically sink. The machine starts to warm up until it is finished and the tin paste can is free. 6. After use, turn off the power switch. 1. In the case of power failure, if the set time is not reached, the solder paste bottle will not be removed. 2. Please keep the machine clean. 3. Check that all screws are not loose. 4. Check the main power switch of the machine before returning the temperature. Machine size:L500*W300*H230(MM) Working voltage: 220V 60HZ Air pressure: 5KG

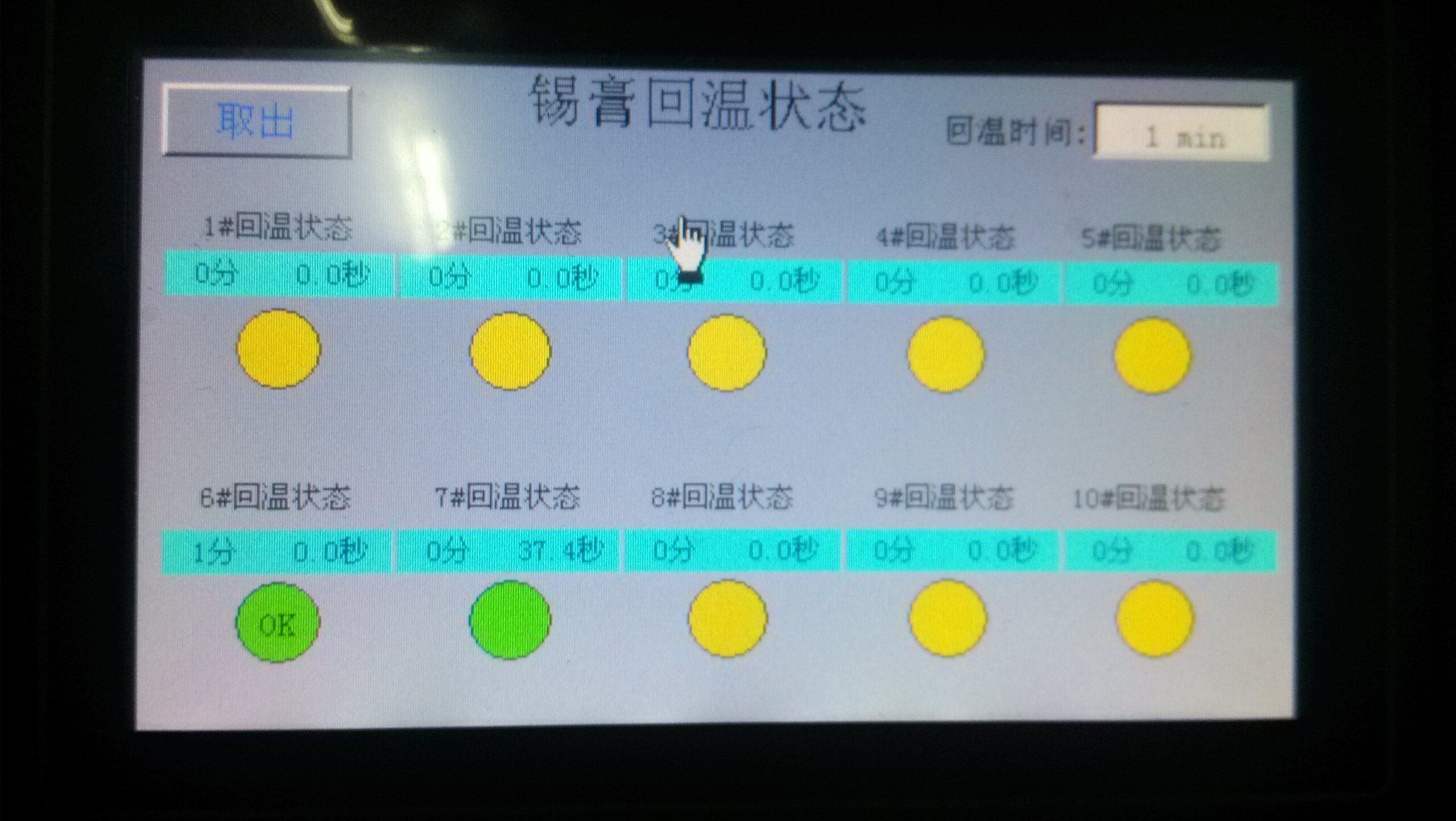

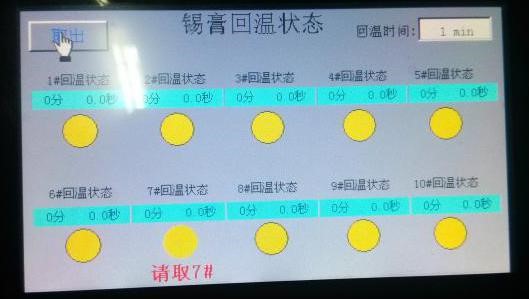

1. Manually put the frozen solder paste in the return temperature, start the timing switch, automatically clamp, start the timing, to the set time to give a signal prompt, can be taken out, not to the set time in the locked state. If it is taken out manually before the time is up, the device will give alarm instructions. 2. The number of hot solder paste can be customized according to requirements. 3. In the case of power failure, if the set time is not reached, the solder paste bottle will automatically pop out. The solder paste is usually refrigerated in the refrigerator, and the refrigeration temperature is 5 to 10 ° C, and the solder paste needs to be stored at such a low temperature to maintain good viscosity. Prevent the separation of various active ingredients, affecting the solder paste welding quality. In order to match the welding process in production, such as printing performance, collapse resistance, release performance, etc., the solder paste needs to be warmed before use. The use of return temperature function is better to solve the problem of natural return temperature, which can effectively help control the production plan and improve the production efficiency. Automatic solder paste reheating machine, professional for solder paste timing reheating control and design. PLC touch screen control, imported electrical parts assembly production. Manually put the refrigerated solder paste into the solder paste tank of the reheating machine, lock the solder paste bottle, and automatically start the timing. After reaching the set return temperature time, the warning device will warn the alarm, the touch screen will display the OK sign, click to take out, the touch screen will prompt the corresponding position of the OK solder paste, and the corresponding solder paste bottle can be taken out manually. The solder paste bottle that has not reached the time is in a dead state and cannot be removed. With first-in-first-out function, such as a time there are several bottles of solder paste OK, the first return to the temperature of the solder paste is not removed, and the later return to the temperature of the solder paste can not be removed. Can be customized with printing, MES system function, scan code system function. 1. Manually place the frozen solder paste bottle in the groove of the return temperature machine, start the timing switch, the return temperature machine will automatically clamp (staff can not pull out with force), start the timing, and automatically give a signal to the set time, you can take it out. 2. 20 bottles of solder paste or more can be heated at the same time (can be customized according to customer requirements). 3. Air source: about 0.6Mpa. 4. Power supply: 220V AC. Set the reset time in the upper right corner. When the temperature is returned, the corresponding solder paste position is displayed in green. The blue part shows the time when the temperature has been returned. After the return temperature is OK, the OK mark is displayed at the corresponding solder paste position. When the temperature return time is up, click the button in the upper left corner to remove it. The touch screen will prompt you to remove the corresponding solder paste position according to the principle of FIFO. You can’t take the paste until you take the paste. 4-slot machine size: L500*W300*H230(mm) 8-slot machine size: L500*W520*H320(mm) 10-slot machine size: L600*W530*H350(mm) 12-slot machine size: L710*W530*H380(mm) 15-slot machine size:L600*W708*H450(mm) 21-slot machine size:L850*W650*H400mm 36-slot machine size:L1200*W650*H710 All products can be customized according to customer bottles and requirements Machine weight: Net weight 4 slots /15KG, 8 slots /35KG, 10 slots /45KG, 12 slots /68KG, 15 slots /45kg, 21 slots /50kg, 36 slots /180KG Working capacity: 500g per can or custom cartridge!Automatic solder paste reheating machine instructions

1. solder paste reheating machine features and functions:

2. solder paste reheating machine operation panel description:

3. Solder paste reheating machine installation and commissioning:

4.solder paste reheating machine operation steps and precautions:

In the case of power failure, if the set time is not reached, the solder paste bottle will automatically eject.5.solder paste reheating machine description:

Button type solder paste reheating machine

solder paste reheating machine features and functions:

Install

Debug

Solder paste reheating machine operation procedure

Announcements

Solder paste reheating machine description

Touch screen solder paste heating machine information

solder paste heating machine description:

Solder paste temperature machine advantages:

solder paste heating machine operation Method:

Solder paste temperature machine size description: