1. silver paste mixer using the principle of 45 degrees centrifugation, through rotation and revolution, so that different components of the material fully mixed evenly, no stratification, no bubbles, stirring defoaming effect is extremely ideal; A processing time only a few minutes, stirring efficiency is very high; 1. Canned bottles 1. The machine is placed near the same power supply as the machine, and the ground is required to be solid and stable. 2. Make sure that the power supply is correct and the power switch is in the OFF/ off position, and insert the power cable. 3. Open the door lock and lift the cover of the machine. 4, place the product tank to be stirred, please tighten the lid of the product tank to be stirred directly into the stirring fixture. 5, if you need to stir two cans at the same time, please make sure that the weight is roughly equal, the difference should not exceed 50 grams. 6, make sure that no tools, gloves and other items are left in the machine. 7, close the top cover, lock the door, close the access switch. 8, turn on the power switch, the timer shows the last set running time. To adjust the running time, press the up or down ↓ button of the up/Down time adjustment button. Each time you press the up/down time adjustment button, the time will increase or decrease by one time until the ideal mixing time is reached. 9, press the start/stop switch, the machine starts to run, the electromagnet action, the top cover is locked and cannot be opened, the running indicator light is on, the motor starts to rotate. 10, at the end of the set time, the motor stops rotating, the buzzer gives an alarm, but the running indicator is still bright, at this time the planet stirring fixture is rotating due to inertia, please do not try to open the cover; One minute later, the planetary stirring fixture completely stops running, the running indicator light is off, the buzzer emits three alarms, the electromagnet is reset and released, and the top cover can be opened at this time; Remove the product can and use.silver paste mixer features:

2.silver paste mixer no stirring appliance extends into the material, no need to clean, will not pollute the raw materials, and will not cause the loss of materials because the mixer takes away the material;

3.Centrifugal silver paste mixer suitable for the mixing of most materials, can mix defoaming silver paste, solder paste, ink, epoxy resin, thermal paste, electronic paste, glue and powder dissolve as one of the various high viscosity products. And does not damage the shape of the material, can greatly improve its efficiency;

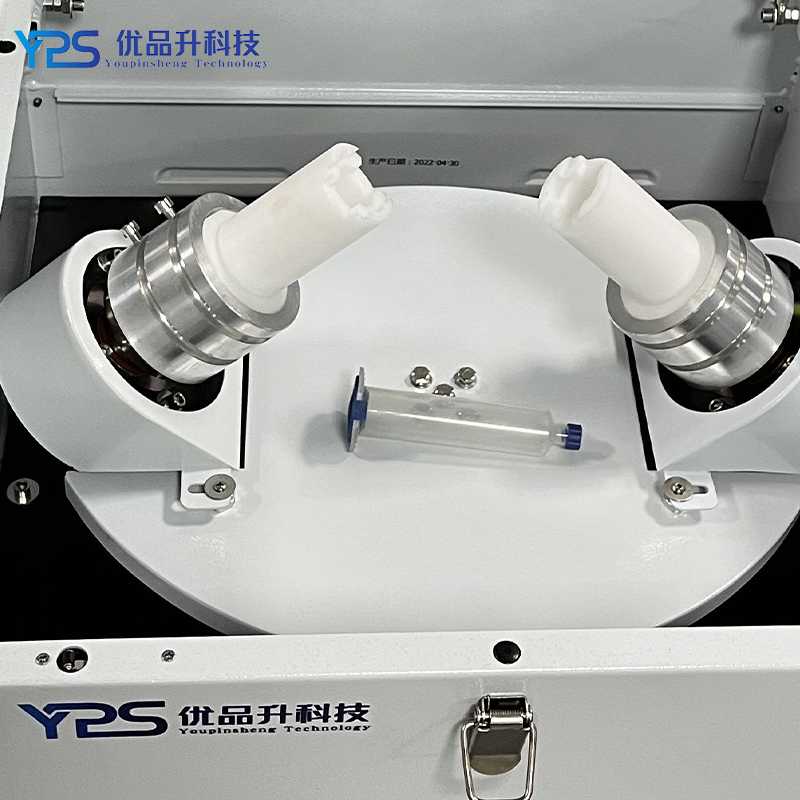

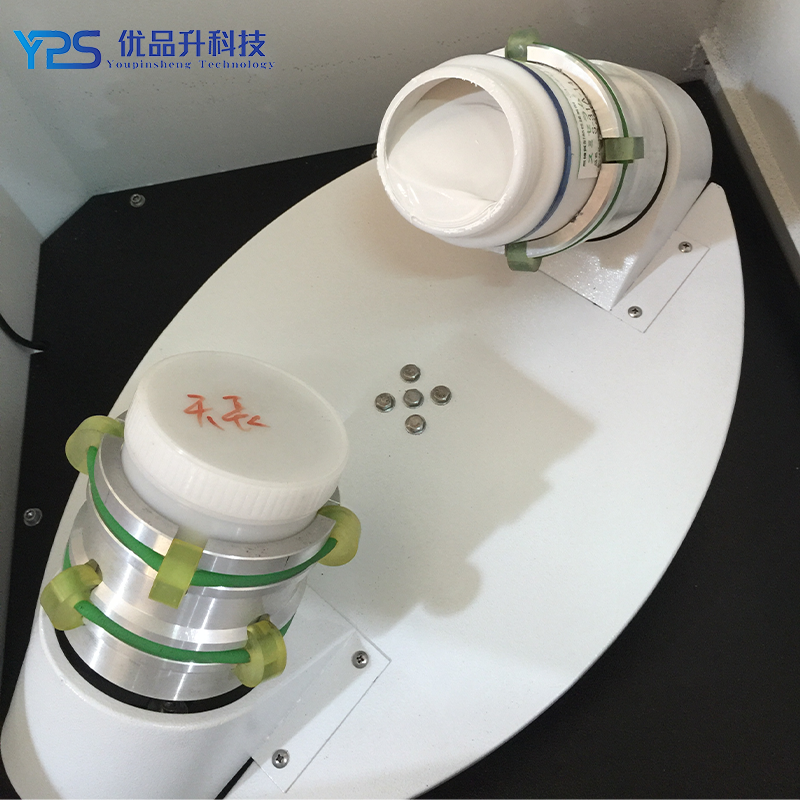

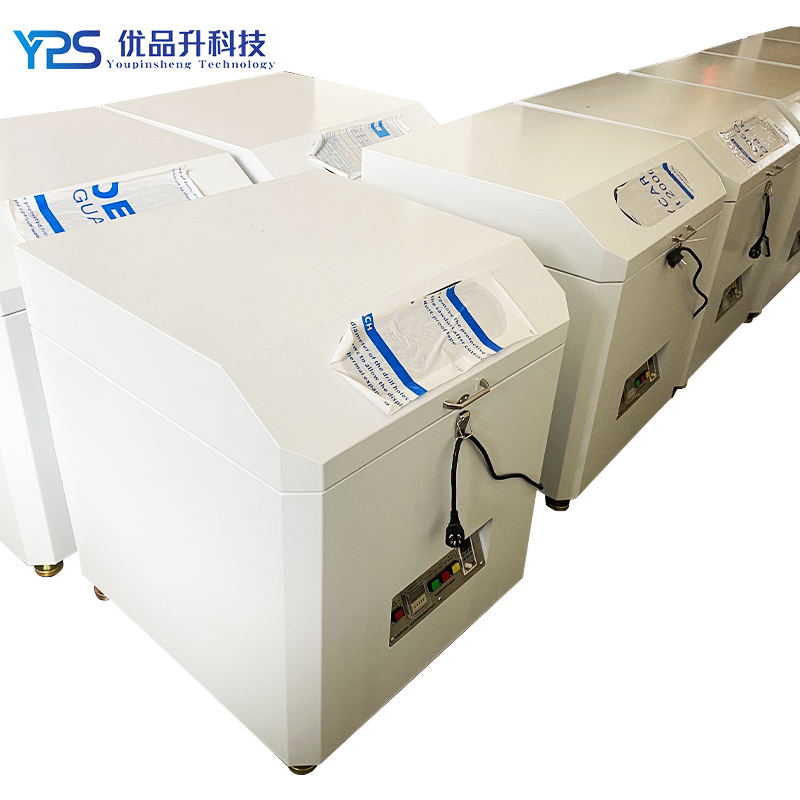

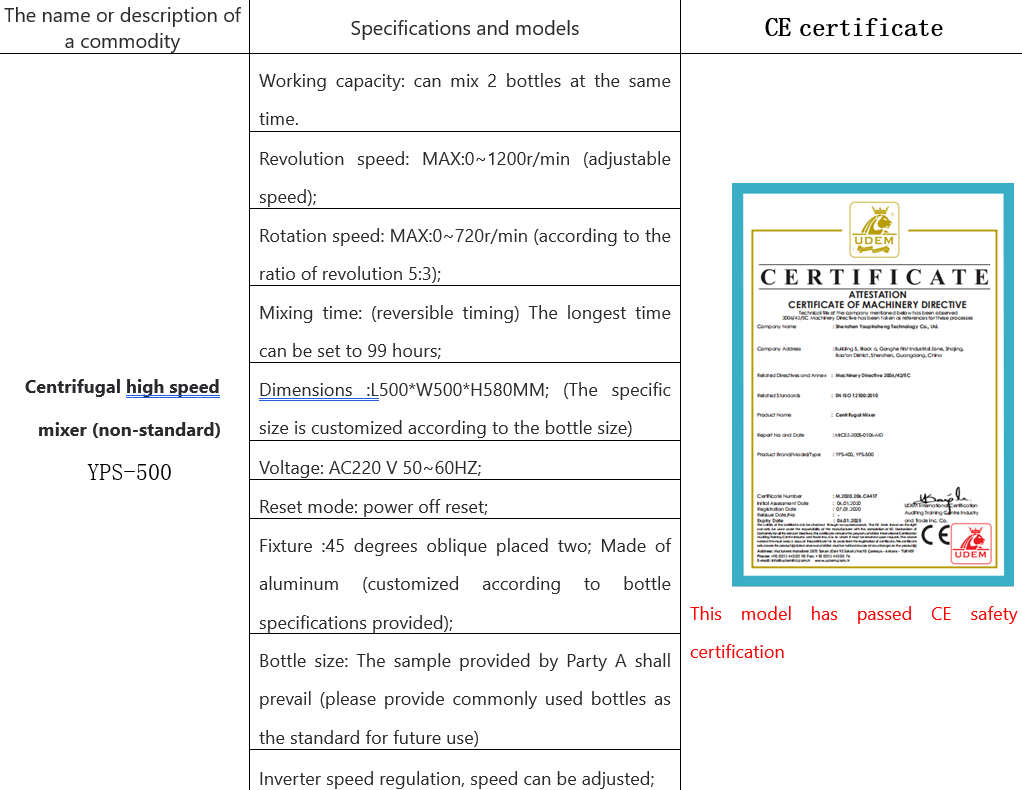

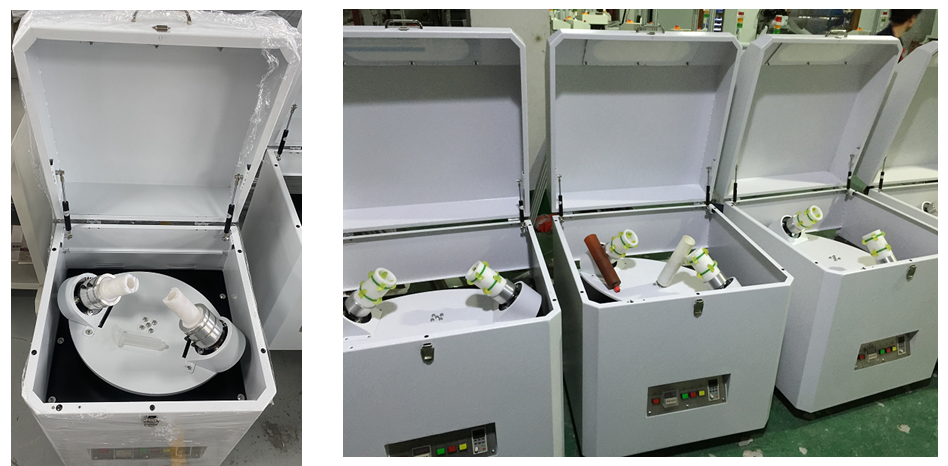

4.all kinds of bottle specifications can be customized, only need you to provide samples; Mix two bottles at a time!silver paste mixer Technical Specification:

The fixture can be customized to different specifications according to customer bottles;

2, Needle bottle

3, variety of different specifications of bottles, can share a machine

Below are the bottle samples provided by each customer; (Provide sample bottles, can be customized fixture)

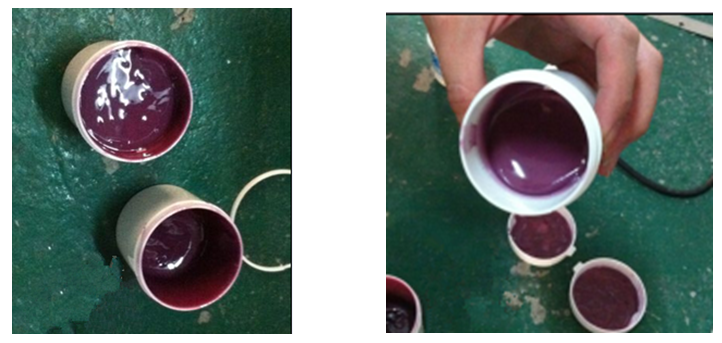

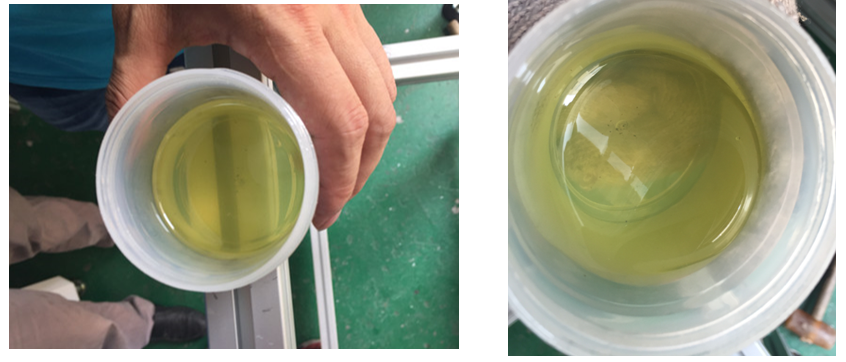

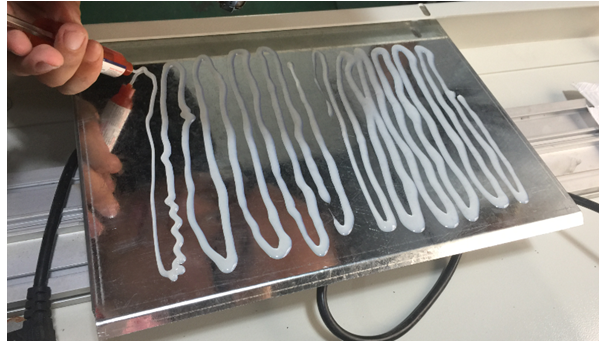

Material mixing comparison:

Comparison before and after stirring epoxy resin for Taiwan customers:

Comparison of powder and glue before and after mixing:

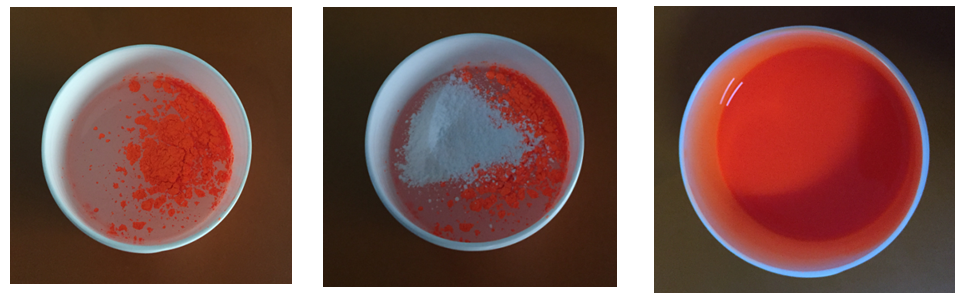

The effect of stirring polyurethane

UV glue after mixing effect:

Effect of iron slurry before and after mixing:

Centrifugal mixer use and operation