The Ultimate Guide to Selecting Your Perfect Vacuum Mixer

Introduction: The Critical Role of Vacuum Mixers in Modern Manufacturing

“In materials science, perfection lies in the absence of voids.” – Dr. Elena Rodriguez, MIT Materials Engineering

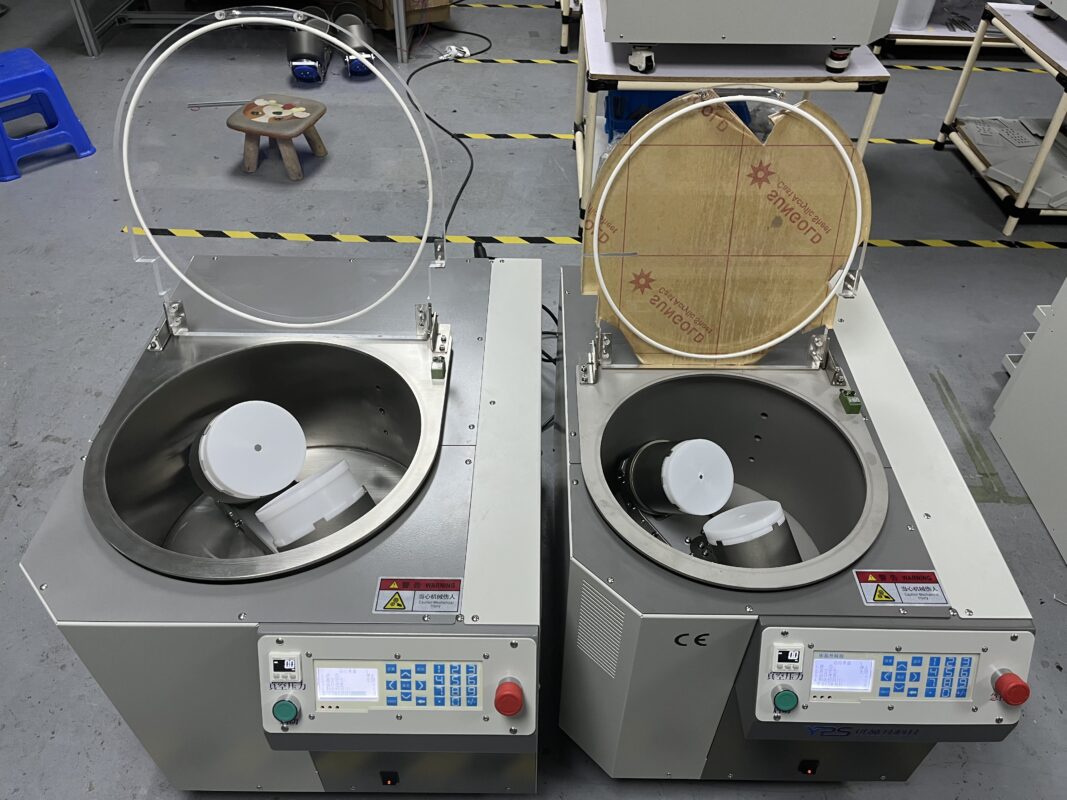

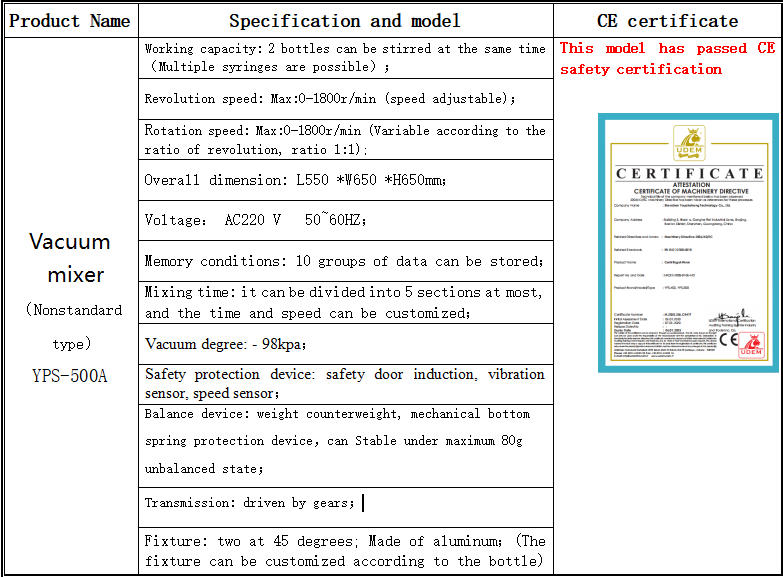

Vacuum mixers have revolutionized precision manufacturing across industries – from aerospace adhesives to medical-grade silicones. At YPS Vacuum Mixers, we’ve engineered industrial-grade mixers that eliminate 99.97% of microbubbles while preventing thermal degradation. This guide reveals how to select equipment that maximizes ROI while ensuring product integrity.

Chapter 1: Core Technical Specifications Decoded

The 5 Non-Negotiables for High-Performance Vacuum Mixers

Centrifugal Force Efficiency

- YPS’s 45° orbital revolution design achieves 5,000 rpm without vortex formation

- Eliminates 10μm bubbles in <90 seconds (industry average: 240 seconds)

Thermal Control Systems

- Gear-driven transmission reduces temperature rise to Δ2°C (vs. typical Δ8-12°C)

- Critical for solder paste curing and pharmaceutical compounds

Vacuum Precision

- 0.095MPa minimum pressure with digital control

- Prevents “outgassing” in silicone encapsulation

Material Compatibility

- Viscosity range: 50,000~1,500,000 cP

- Chemical resistance: Acids (pH 0.5-2), solvents (acetone/IPA), and UV-curable resins

Cleanability & Contamination Prevention

- Sealed chamber with Ra≤0.8μm surface finish

- Zero direct material contact (no shaft/blade contamination)

Chapter 2: Comparative Analysis - Standard vs. YPS Industrial Vacuum Mixers

| Parameter | Entry-Level Mixers | YPS Precision Series | Impact on Production |

| Mixing Efficiency | 85-90% bubble elimination | 99.97% bubble elimination | Eliminates rework costs |

| Temperature Control | ±8°C fluctuation | ±1°C precision | Prevents premature curing |

| Chamber Seal | Silicone gaskets (6-mo life) | PTFE-Kalrez hybrid seals(5-yr warranty) | Reduces maintenance downtime |

| Control Interface | Basic buttons | 10" HMI with recipe memory | 40% faster batch changeover |

| Max Viscosity | 500,000 cP | 1,500,000 cP | Handles thick pastes/inks |

| Customization | Limited size options | Tailored chamber geometries | Perfect for R&D prototypes |

Chapter 3: Real-World Applications - Solving Industry Pain Points

Case Study 1: Lithium Battery Electrode Slurry

- Challenge: CNT agglomerates causing “dead zones” in batteries

- YPS Solution: » Dual-speed centrifugal mixing (200/1200 rpm) » Argon-inerted vacuum environment

- Result: 15% increase in energy density for EV battery client

Case Study 2: Medical Silicone Production

- Challenge: Voids in breast implant fillers failing FDA tests

- YPS Solution: » -0.098MPa vacuum with degassing pauses » Jacketed cooling maintaining 22±0.5°C

- Result: Zero defect rate over 12,000 units

FAQ: Expert Answers to Critical Questions

Q: Why does centrifugal mixing outperform blade systems? A: Blades shear materials (damaging CNTs/grahene) and trap air. Our planetary motion mixes without contact – preserving nanostructures.

Q: How to choose between benchtop vs. floor-model vacuum mixer machines? A: Match capacity to batch volumes:

- <5L: Benchtop (YPS B-Series)

- 5-20L: Pilot-scale (TS-Series)

- 20-100L: Industrial (IS-Series)

Q: What maintenance do vacuum mixers require? A: YPS systems need only: » Quarterly seal inspections » Annual bearing lubrication (kits included) » 5-minute HMI calibration

Q: Can I process abrasive ceramics? A: Yes – specify tungsten carbide-coated chambers when ordering. Handles SiC/Al₂O₃ slurries.

Q: Why is temperature control vital for solder paste? A: Flux activation starts at 38°C. Our Δ1°C control prevents premature reaction flux viscosity changes.

Engineer-Approved Recommendations

For R&D Facilities

- Model: YPS B-3V

- Capacity: 3L

- Key Feature: Recipe memory for 200 formulations

For Medical Device Mfg

- Model: YPS TS-10Med

- Capacity: 10L

- Certification: ISO 13485 compliant

For Battery Material Production

- Model: YPS IS-50Batt

- Capacity: 50L

- Specialty: Argon purging & explosion-proof design

Partner with YPS for Precision Mixing Solutions

Ready to Eliminate Defects & Boost Yields?

- Technical Consultation: Send material specs to Abby@szyops.com

- Performance Demo: Schedule live Zoom factory testing

- Custom Engineering: Receive 3D design in 72 hours

📞 Direct Engineer Line: +86 13480152150 (Signal/WhatsApp)

🌐 Product Gallery: https://szyops.com/product/vacuum-mixer/

“We don’t just sell mixers – we provide void-free futures.” – Dr. Qin, Chief Engineer at YPS Vacuum Mixers

Abby

Professional SMT Equipment Sales Engineer:

Proficient in various product expertise and supplier systems, helping you find SMT products with better cost-performance ratios.