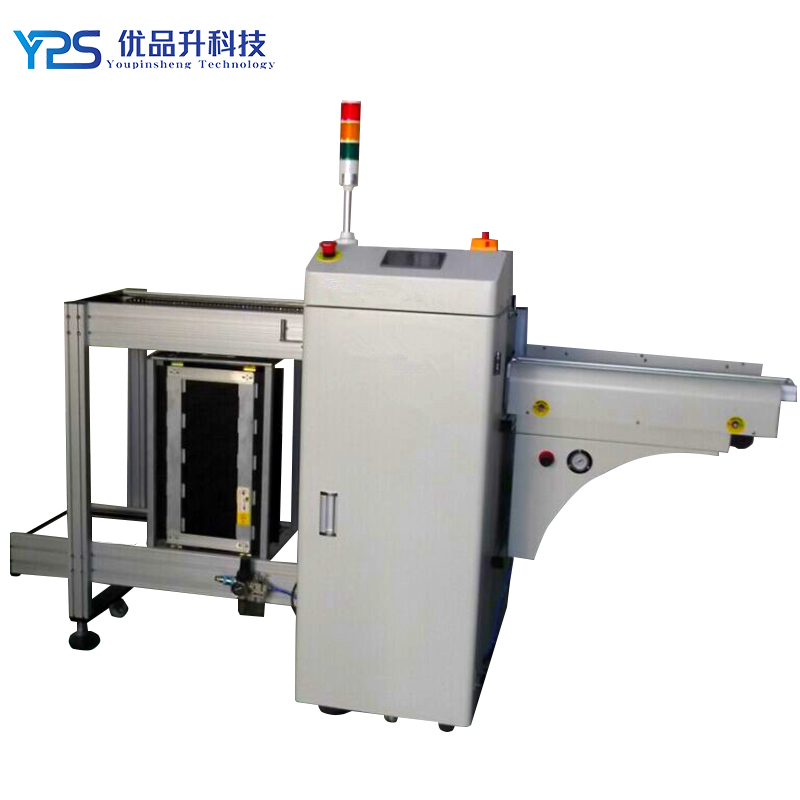

How to choose the best PCB unloading machine

Introduction:The Critical Role of PCB Unloading Machines in SMT Production

In the fast-paced world of SMT equipment manufacturing, efficiency and precision are non-negotiable. A high-quality PCB unloading machine ensures smooth production flow, minimizes human error, and maximizes throughput. At YPS Technology, we specialize in designing PCB loading and unloading machines that integrate seamlessly into automated SMT lines, offering reliability, speed, and customization.

This guide will walk you through the key factors to consider when selecting the best PCB unloading machine for your production needs.

Chapter 1: Key Features of a High-Performance PCB Unloading Machine

1. Automation & Precision

- PLC Control System (Preferably imported brands like Mitsubishi or Siemens)

- High-precision SMC rodless cylinders (Japanese imports for smooth operation)

- Automatic counting & height adjustment (Prevents PCB damage)

2. Durability & Structural Integrity

- Thickened aluminum alloy frame (Resists vibration & wear)

- Corrosion-resistant materials (Essential for long-term use)

3. Flexibility & Customization

- Adjustable for different PCB sizes (Supports flexible production)

- Compatibility with upstream/downstream SMT equipment

4. Safety & Fault Detection

- Automatic alarm for jams or misalignment

- Emergency stop function

Chapter 2: Comparison of PCB Unloading Machine Specifications

To help you make an informed decision, here’s a detailed comparison of standard vs. premium PCB unloading machines:

| Feature | Standard Model | YPS Premium Model | Why It Matters |

| Control System | Basic PLC | Mitsubishi PLC | Ensures stability & precision |

| Cylinder Type | Domestic rodless cylinders | SMC Japan rodless cylinders | Smoother operation, longer lifespan |

| Frame Material | Standard aluminum | Thickened patent aluminum | Higher durability, less vibration |

| Height Adjustment | Manual | Auto-adjust (Max 10 steps) | Prevents PCB damage |

| Alarm System | Basic fault detection | Smart error alert + auto-stop | Minimizes downtime |

| Customization | Limited PCB size support | Fully adaptable to customer specs | Future-proof investment |

Chapter 3: Why Choose YPS as Your SMT Equipment Manufacturer?

1. Advanced R&D Team

- 20+ years of SMT automation expertise

- Custom solutions for unique production needs

2. Rigorous Quality Control

- CE, ISO, and RoHS certified

- 100% pre-shipment testing

3. Global After-Sales Support

- 24/7 remote troubleshooting

- On-site technician dispatch (if needed)

4. Customization Options

- MOQ: 1 unit (No bulk order required)

- OEM/ODM services available

Chapter 4: Common Applications of PCB Unloading Machines

✔ SMT Production Lines – Automated unloading after reflow soldering

✔ PCB Testing Stations – Safe transfer to AOI or functional testers

✔ High-Mix PCB Assembly – Adjustable for different board sizes

FAQ: Expert Answers on PCB Unloading Machines

Q: What’s the main advantage of an automated PCB unloading machine?

A: It reduces oxidation on solder pads (vs. manual handling) and cuts labor costs by 70%.

Q: How do I know if a machine fits my PCB size?

A: YPS machines support custom sizing—just provide your PCB dimensions.

Q: What’s the lead time for a custom model?

A: 7-10 days for design, 30-45 days for production.

Q: Do you offer installation support?

A: Yes! We provide video guides, remote setup assistance, and on-site service.

Q: What maintenance is required?

A: Just monthly lubrication and sensor cleaning—we include a maintenance manual.

Upgrade Your SMT Line with YPS Technology

At YPS, we don’t just sell machines—we engineer solutions that boost your productivity.

📩 Email us: Abby@szyops.com

📞Call/WhatsApp: +86 13480152150

🌐 Learn more: www.yps-smt.com

“Precision unloading starts here—let’s automate your success!” – YPS Technology Team

Abby

Professional SMT Equipment Sales Engineer:

Proficient in various product expertise and supplier systems, helping you find SMT products with better cost-performance ratios.