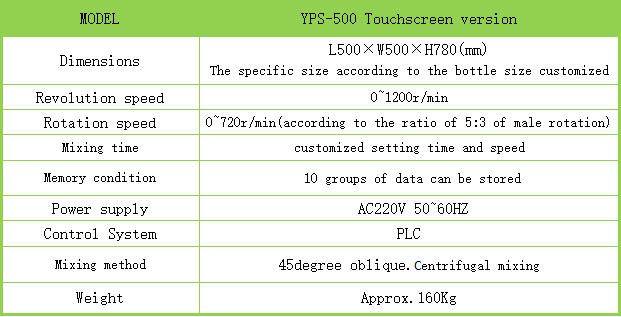

Working principle of high-speed planetary centrifugal mixer:

The high-speed planetary mixer adopts a planetary transmission method (revolution+rotation), which applies centrifugal force equivalent to the weight of hundreds of materials themselves to the materials in the carrier cup (or carrier), and then combines the rotation of the materials with each other to achieve rapid and uniform multi-component materials.

The strong centrifugal force of the machine itself causes bubbles inside the material to escape from the body under this force, which has the function of removing material bubbles.